Dodge Ram: Why is My Brake Pedal Soft?

Your brakes should immediately respond when you touch the pedal, which shouldn't go all the way down when depressed. Learn what could be causing this issue here.

This article applies to the Dodge Ram (1994-present).

It is always good when your truck starts and moves, but the really important thing you always want to have available are good brakes. Nothing is scarier than pulling up to an intersection and your brake pedal goes to the floor before finally stopping. A reliable brake system on your truck is all about hydraulic pressure created by the master cylinder and transferred to the wheels without any issues. The brake fluid transfers the pressure created but can only do so reliably if there is no air in the system nor any leaks. So lets look at some common problems that may cause you to throw an anchor out the window to stop rather than just press down the pedal.

Materials Needed

- Brake fluid approved for your truck

- Appropriate sized wrench for brake bleeder screws

- Clear tubing that fits bleeder screw

- Vacuum bleeder kit

- Jack and wrench to remove rear wheel

- Large screwdriver or brake adjuster wrench

Step 1 – Check brake fluid

If you are adding brake fluid to your truck, your pedal will never be firm. Brake systems do NOT use fluid. You have a leak that must be repaired ASAP. It could be the master cylinder, wheel cylinder, caliper, or a bad line.

Pro Tip

Driving your truck with the brake system leaking is an accident waiting to happen. Find and repair any leak immediately.

Step 2 – Bleed brakes

The overwhelming reason for a soft brake pedal is a system that needs to be bled. Even if you just installed a complete new brake system with pads, shoes, wheel cylinders, master cylinder, and bled it pretty well that may not be enough.

Manually bleed the brakes. Start at the rear passenger side, then the rear driver's side, then the front passenger side, and finally the driver's front.

- Get the proper sized clear tube and a container with some brake fluid in it. Put the tube over the nipple on the bleeder screw. Have a helper slowly push the brake pedal to the floor and hold it there. Now loosen the bleeder and allow the line to bleed. When the pedal is on the floor tighten the bleeder back up, and only then they can let off the pedal. Repeat four or five times for each cylinder, until there are no air bubbles, and you are totally sure no air is trapped in the lines.

- Keep the end of the tube submerged in brake fluid in the container to avoid the possibility of sucking in any air. Keep an eye on the brake fluid level in the master cylinder, refilling as necessary so no air is allowed to get in the lines. Sometimes it can take a lot of bleeding to get all of the air out.

Shops use a vacuum bleeder that sucks the fluid out of the lines, which is particularly effective. With one of these, if you cannot dull a vacuum on a line, then you'll know for sure that there is a leak in the system for that wheel. You can also purchase a simple vacuum bleeder kit that works very well. Once again, be sure that the master cylinder never runs low on brake fluid or your efforts will be ruined.

If your pedal is not quite firm enough yet, move on to Step 3.

Pro Tip

Brake fluid is backward compatible in most cases, meaning that Dot 4 is acceptable to use in place of Dot 3; however, synthetic brake fluid should not be mixed with mineral-based fluids.

Step 3 – Adjust rear brake shoes

The rear drum brakes on your truck have self adjusters that are supposed to keep them adjusted; however, sometimes you need to help them out by adjusting them manually.

- Lift a rear wheel on your truck and remove it.

- Remove the brake drum. This can be easy if it has been removed recently but more difficult if it has been on for awhile.

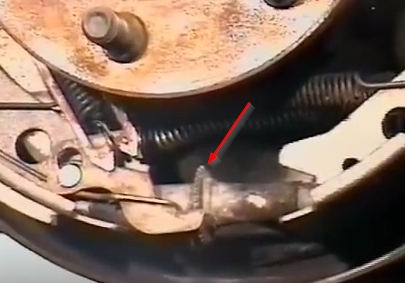

- Clean the inside of the drum well. The adjuster for the brakes is at the bottom and looks like the one in Figure 3.

- Adjust the star wheel out until the shoes rubs the drum slightly. This takes up any slack or softness you may feel in the pedal.

- Replace the drum and move to the other side.

Pro Tip

If you are lucky, the drum will slide off easily. There is no easy way to get a stuck drum off except patience and maybe a big hammer.

Now the brake system should be bled completely and the rear drums adjusted properly. The brake pedal should now be firm. If it is not, there is no shame in taking your truck to a professional. The most important thing is to be sure your brakes work properly.

Related Discussions

- Excessive Brake Pedal Travel or Soft Pedal - DodgeForum.com

- Soft Brake Pedal Need Advice - DodgeForum.com

- Soft Brakes - DodgeForum.com

- Brake Pedal Almost to Floor Sometimes - DodgeForum.com

- DIY Front Brakes and Caliper Replacement - DodgeForum.com