Dodge Ram 1994-2001: The Ultimate Drive Shaft Guide

Is it time to replace the drive shaft in your Dodge Ram? This article will show you how it's done. Plus, here you will read about the most popular brands of drive shafts to help you choose which best suits your truck.

This article applies to the Dodge Ram 1500 (1994-2001).

No matter what type of truck you have, or whether it has 2WD or 4WD system, the drive shaft plays an integral role in propelling you down the road. The simple, tubular, cylindrical hunk of metal (also known as the propeller shaft) transfers the power generated by your engine to the front and rear differentials as well as axles, which enables them to turn your truck's wheels to put it in motion. The twisting and turning motion of the drive shaft is referred to as torque, and excessive amounts of torque can cause the drive shaft to bend and break. Drive shafts that aren't straight and balanced are susceptible to vibration, damage, and (ultimately) failure.

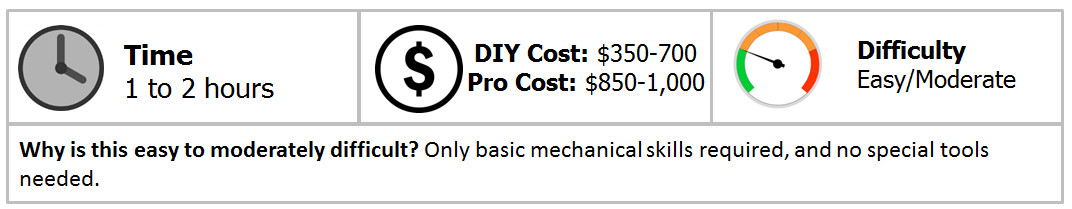

Replacing a drive shaft may seem intimidating, but the task isn't too difficult. You can expect to pay between $250 and $700 for a new one, plus another $50 to $70 for U-joints. If you take it to a professional for installation, expect to pay an additional $150 to $250 in labor costs.

Table of Contents

Drive Shaft Review

With so many different kinds of drive shafts on the market, it can be hard to decide which one is best for your Dodge Ram. There are almost a dizzying array of choices, many of which are made out of different materials, come in different sizes, and have different sized U-joints. Depending on what you use your truck for and how you drive it, there is an option for everyone.

Shaftmasters |

A1 Cardone |

ProComp |

Precision Shaft Technologies |

Visteon | |

|---|---|---|---|---|---|

Price |

$750 | $100-$300 | $400-$600 | $200-$1,000 | $800 |

Style |

Aftermarket | OEM | Aftermarket | Custom | OEM |

Material |

Steel/Aluminum | Steel/Aluminum | Steel | Steel/Aluminum, Carbon Fiber | Steel/Aluminum |

Warranty |

30 Day Limited | 1 Year/18,000 miles | Limited Lifetime | Optional Lifetime | 1 Year Limited |

Best Value: A1 Cardone

Shaftmasters

Price – $750

Style – Aftermarket

Material – Steel/Aluminum

Warranty – 30 Day Limited

Shaftmasters makes quality, OEM drive shafts that are a direct, bolt-in replacement for stock drive shafts. These drive shafts come with serviceable U-joints, which the stock units do not have. This convenient feature enables you to replace only the U-joints when they go bad, as opposed to replacing the entire drive shaft. The pricing is a little high, especially when you consider the cost of some of the custom choices available. Shaftmasters drive shafts, however, do come with all of the installation tools needed and can be bought off the shelf rather than you waiting for a custom unit to be built. Recommended if you want a quality, OEM-style unit that is easy to service and you don't mind paying for it.

A1 Cardone

Price – $100-$300

Style – OEM

Material – Steel/Aluminum

Warranty – 1 Year/18,000 Miles

Unlike the other choices, A1 Cardone exclusively offers rebuilt OEM units instead of producing new ones. If you don't mind waiting two to three weeks while your drive shaft is rebuilt, this option is an economic alternative to purchasing a new unit. A1 Cardone has a solid reputation for their quality work. Recommended if you don't mind waiting, but want to save a ton of money.

ProComp

Price – $400-$600

Style – Aftermarket

Material – Steel

Warranty – Limited Lifetime

ProComp is well known in the off-road community for making high quality drive shafts that are made specifically for lifted vehicles. Because they are longer than OEM drive shafts, ProComp units eliminate the vibrations present in stock applications. As you can imagine, this also means you are going to pay a premium price for this premium product. Recommended for serious off-roaders and those with lifted trucks.

Precision Shaft Technologies

Price – $200-$1,000

Style – Custom

Material – Steel/Aluminum/Carbon Fiber

Warranty – Optional Lifetime

Precision Shaft Technologies makes quality drive shafts that are easily serviceable since they contain replaceable U-joints. Because they are custom built for your application, there is a wait time involved. However, they are also cheaper than some OEM options. For these reasons, it's hard not to view PST drive shafts as a good option. Recommended if you don't mind waiting a bit for a high quality drive shaft at a good price.

Visteon

Price – $800

Style – OEM

Cleanable – Steel/Aluminum

Warranty – 1 Year Limited

If you're a stickler for keeping your truck as close to the factory setup as possible, Visteon produces new OEM-specific drive shafts. Unfortunately, they are also expensive. And since they are identical to the stock drive shafts, you also lose the option of replacing the U-joints separately. Recommended only if you want a brand new, OEM replacement and nothing else.

How to Replace Your Drive Shaft

In 4WD Dodge Rams the drive shaft is connected to the transfer case, as opposed to 2WD Dodge Rams where the drive shaft is connected directly to the transmission. In either case, removal of the drive shaft is generally the same procedure. A few symptoms can indicate that your truck's drive shaft needs to be replaced: you feel a vibration coming from the floorboard, or hear a low squeaking sound from underneath the truck when increasing in speed. You can also manually inspect the drive shaft by putting your truck in neutral, engaging the emergency brake, sliding underneath, and moving the yokes of the U-joints. If there is excessive back and forth movement or the joints rotate too freely (or difficult to rotate at all), the drive shaft may need to be replaced.

Materials Needed

- 12mm socket

- Large flat-ended punch tool

- Large hammer

- Pliers

- File

- New grease

- WD-40

- Brake cleaner

- Floor jack and jack stands

- Wheel chocks (4)

- Transmission fluid

- Paper towels

Step 1 – Prep the installation

Before you begin, it's important to lift up your truck as the drive shaft is located along the center of the undercarriage. Make sure you park on a flat, level surface to prevent the truck from rolling. Engage the parking brake and chock all four wheels. Taking these precautions will keep the truck from rolling away once the drive shaft is removed.

Step 2 – Remove old drive shaft from the transmission

- Drive shafts are heavy components, so have a friend assist you if possible.

- If you don't have an air wrench, spray the drive shaft bolts with WD-40 or Liquid Wrench and let sit for a few minutes. These bolts can get very rusty and be tough to remove.

- Line the ground beneath the ends of the drive shaft with paper towels, near where it connects to the transmission.

- Use the 12mm socket to remove the bolts that connect the drive shaft to the rear differential.

- Carefully slide the drive shaft out from the transmission, and set it aside.

Figure 2. Remove the drive shaft bolts.

Figure 3. Drive shaft removed.

Step 3 – Remove the U-Joint

You only need to complete this step if you are replacing the U-joints. Usually, most new drive shafts come with U-joints already installed.

- Remove the C-clip on both sides of the U-joint using a pair of pliers. Do so by squeezing the middle section of the C-clip and pulling it out.

- Use a punch and hammer to push out one side of U-joint, and then knock out the bearing race on the opposite side.

- Remove the U-joint and set it aside.

Step 4 – Install the new U-joint

- Remove the two bearing races on the new U-joint, and then place the U-joint in the yoke.

- Carefully push the first race into place, taking care not to dislodge the needle bearings in the race.

- Lightly tap the race into place, and repeat on the other side.

- Once the race is aligned with the C-clip grooves, install the clips on both sides.

Step 5 – Install the new drive shaft

To install the new drive shaft, simply reverse the order of removal.

- Set the transmission side of the drive shaft in first. Make sure that the missing tooth in the splines of the drive shaft lines up with the transmission.

- Re-install the bolts connecting the the drive shaft into the differential.

- Check your transmission fluid level and top off if necessary.

-

Featured Video: Bad Drive Shaft and U-Joint

-

Featured Video: Dodge Drive Shaft Rebuild

Related Discussions

- How to Remove Rear Drive Shaft and U-Joints - DodgeForum.com

- Front Drive Shaft U-Joint Replacement - DodgeForum.com

- Balance Your Drive Shaft - DodgeForum.com