Dodge Ram 2009-Present: Why is My Truck Leaking Oil?

An oil leak often indicates a failing seal somewhere on your Ram truck. While some leaks are minor and may not require immediate attention, a severe leak should be fixed to ensure a safe and properly operating vehicle.

This article applies to the 4th Generation Dodge Ram 1500 (2009-Present).

Modern vehicles use a variety of different oils and fluids essential for proper vehicle operation. As a vehicle ages and accumulates mileage, many rubber seals that keep oils in place can dry up, tear, or loosen, resulting in an unfortunate leak. Similarly, bolts and fasteners can loosen from vibration and also lead to an oil leak. If left unattended, these leaks can make a mess of the truck's undercarriage as well as your driveway. Additionally, ongoing leaks can eventually cause major component wear and damage if oil levels become severely low. Spending some time to properly determine the source and severity of your Ram's oil leak will allow the proper action to be taken, if necessary. Often times, an oil leak can be a quick and inexpensive fix; however, some fixes can be much more in-depth and require major components to be removed from the truck for a complete fix. Either way, this article will outline typical oil leaks that can occur on the fourth generation Dodge Ram 1500.

Materials Needed

- Engine degreaser

- Pressure washer (optional)

- Shop rags

- Racthet, sockets, and wrenches

Step 1 – Clean undercarriage and examine the leaking oil

- Determining the source of an oil leak can be quite a chore in itself, but trying to locate the leak with a dirty undercarriage can be nearly impossible. With the forces of gravity in action, any oil leak will make its way down to the bottom of the car and is often blown toward the rear of the vehicle. This can become quite messy and will hide the true source of the leak. Thoroughly clean the engine/undercarriage of the truck before getting too deep into searching for the leak. This is not to say that looking for a leak prior to cleaning is a bad idea, but generally speaking, a clean truck will allow for a quicker diagnosis.

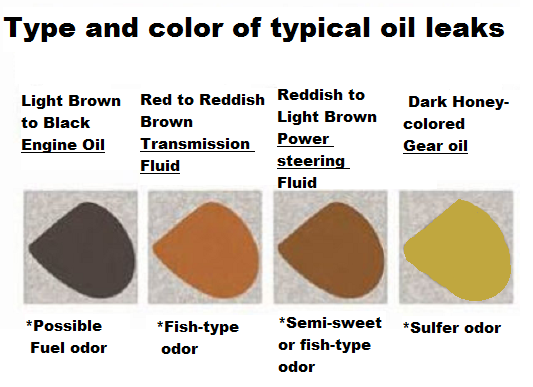

- In addition to cleaning, a quick examination of the type of oil that has leaked out of the truck can help pinpoint a general area to inspect. Each type of oil used in the Ram typically has a distinctive color and odor that can lead you to the component that may be leaking. The chart in Figure 1 illustrates a good representation of the color and odor of the different oil types.

Figure 1. Types of oil leaks.

After examining the type of leaking oil and cleaning the undercarriage, inspect the components that contain the type of leaking oil found.

Step 2 – Check for engine oil leaks

If the type of leaking oil you have discovered is engine oil, there are a few typical places where it may be coming from.

-

Oil filter or oil pan drain plug: Perhaps the most common area of leaking engine oil is the engine's oil filter or oil pan drain bolt. Spin-on oil filters have a rubber seal on the leading edge that can become damaged during installation and will subsequently leak. Additionally, these seals can remain on the flat surface of the filter housing when the old oil filter is removed and will leak if a new filter is installed over the top of the old seal. Similarly, oil pan drain bolts will usually have a crushed washer or oil seal that should be replaced on each oil change. When these items wear out, small quantities of oil can leak past the threads of the drain bolt. Be certain that both the oil filter and the oil pan drain bolt are properly tightened to manufacturer specifications.

-

Oil pan: With the inherent vibrations of an engine, it is surprisingly common for the engine's oil pan bolts to loosen and start weeping oil. It is recommended that these pan bolts be inspected during every oil change as they have the tendency to loosen on trucks with as little as 10,000 miles on the odometer. If snugging up the bolts does not cure the pan leak, oil pan gaskets are readily available and can be easily replaced.

-

Main seal: Oil seepage at the front or rear of the oil pan is often an indication of a leaking rear main seal or front crankshaft seal. These areas have been known to leak if the PCV (positive crankcase ventilation) valve has failed and is causing excessive pressure to build inside the crankcase and pushing oil past the seal. Unfortunately, these items can also fail from age. Replacement of either seal is quite in-depth and requires removal of the transmission or various engine accessories to access the failed seal.

-

Cylinder head: A good number of Ram owners have reported oil leaks from the engine cylinder heads. With the fourth generation Ram still being fairly new, most of these leaks can be fixed under warranty. Whether it is manufacturing defect or just a case of a blown head gasket, oil can run down the side of the engine block and eventually make its way down to the oil pan. It is important to thoroughly clean the area to help identify a cylinder head leak as they can contaminate the rest of the engine with oil, making it difficult to spot the source.

If no leak is found around the engine, move on to the following step.

Step 3 – Check for transmission oil leaks

If the type of oil leaking is determined to be transmission fluid, there are only a limited number of places it may be leaking from.

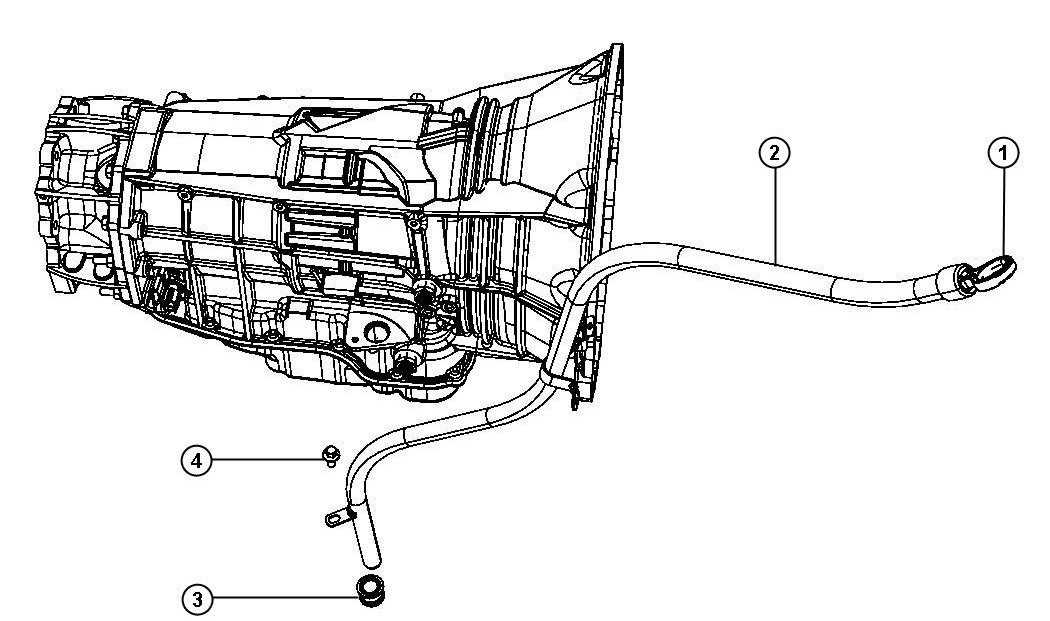

- Dipstick tube: A common source of a transmission fluid leak stems from the oil filler tube. The tube has a small oil seal where it "plugs" into the transmission and keeps oil in while keeping harmful contaminants out. These filler tubes are typically held in with a single bolt that can loosen and allow play in the filler tube, thus causing a leak. Re-securing the tube in place will often cure the leak, but a failed seal can also be easily replaced. This is also applicable to the engine oil dipstick tube.

- Input/Output shaft seal: If transmission oil is accumulating between the engine oil pan and transmission, a bad transmission input shaft seal is the source of the leak. This type of leak will require removal of the transmission for repair. If the leak is at the tail of the transmission, the output shaft seal is likely the cause. This seal can be accessed with the transmission still installed in the truck by dropping the driveline and removing the yoke.

-

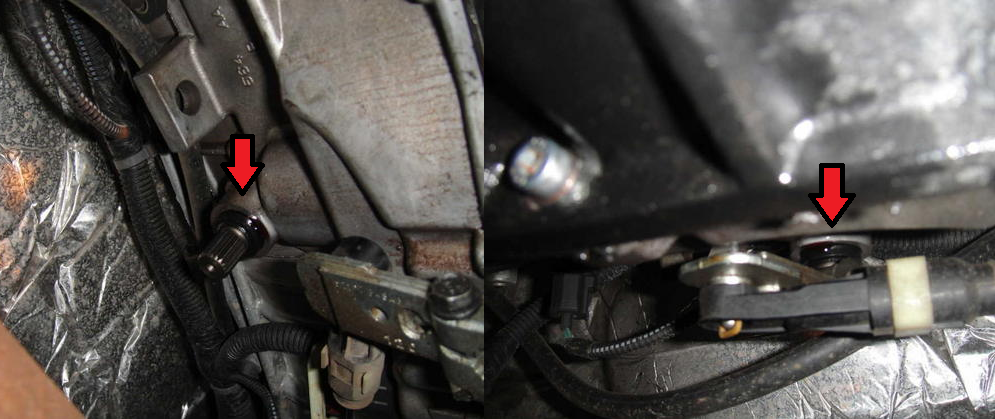

Shift shaft selector seal: The shaft for the shift selector mechanism on the transmission is another potential source for a transmission fluid leak. This seal can be replaced with the transmission still installed in the truck by removing the shift selector linkage and swapping out the old seal with the a new one.

- Transmission pan: As with the engine oil pan, check the tightness of the transmission pan bolts because a loose pan will seep oil. Pan gaskets are also available and it is recommended to service the transmission fluid as well as filter if the need for a new pan gasket arises.

If no leak is found around the transmission, move on to the following step.

Step 4 – Check for power steering fluid leaks

Leaking power steering fluid indicates a fault in the power steering system.

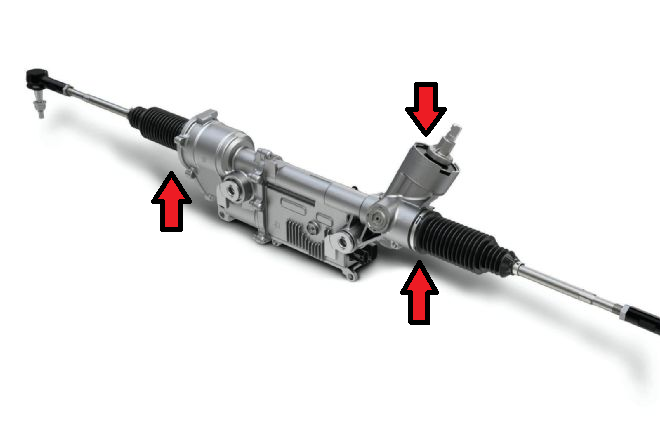

- Steering rack: The steering rack can leak from a variety of places. Either end of the rack can blow a seal and leak fluid into the dust boots. Signs of this type of leak are usually a moaning power steering pump, which can be heard before oil is visibly leaking; but in either case, the steering rack will need replacement. The steering input shaft also contains an oil seal that can leak; however, this seal is serviceable with the steering rack still installed in the truck.

- Power steering pump and lines: The power steering system is a sealed system that uses oil and a pump to aid in pushing the steering rack in the desired direction. The power steering pump operates at high pressure and can see a lot of stress, especially if forced against the steering stops, thus blowing a seal. Additionally, leaks can occur at any of the power steering lines running from the pump to the steering rack. Inspect all connections to ensure they are properly tightened, and make sure they have no cracks or fatigued areas at the fittings that could be leaking.

If no leak is found around the power steering system, move on to the following step.

Step 5 – Check for gear oil leaks

Driveline components: If it is determined that a gear oil leak is present, it is coming from the differential or axle. The differential uses incoming power from the transmission (or transfer case for 4WD truck models) to drive the wheels. Leaks will usually develop at the pinion seal, which is easily fixed by removing the driveline and pinion yoke and by swapping in a new seal. While less common, a leak near either wheel is associated with an axle leak. The differential housing also has the potential to leak, but cases are few and far between, and are typically caused by impact with road debris.

Related Discussions

- Oil leak Above Filter - DodgeForum.com

- Front Axle Seal Leak - DodgeForum.com

- Hemi Ram Leaking Oil - DodgeForum.com