Dodge Ram 2002-2008: The Ultimate Driveshaft Guide

You want to replace your truck's driveshaft. Should you get one made from aluminum? Should you go from your current two-part design to a single shaft? Continue reading to learn which one is best for your Ram.

This article applies to the Dodge Ram (2002-2008).

The longest component of a your truck’s drivetrain is the driveshaft. It connects the transmission to the rear differential in 2WD trucks. In 4WD trucks, it connects the rear output of the transfer case to the rear differential and a shorter driveshaft going to the front axle.

Table of Contents

How to Replace Your Driveshaft

The driveshaft connected to the rear differential is actually referred to as a “propeller” shaft, or “prop” shaft for short. It consists of a splined slip joint (or slip yoke) to accommodate the back and forth movement of drivetrain components, as well as a universal joint (Cardan or just U-joint) at both ends of the shaft to accommodate differing angularity.

As the distances between the transmission, transfer case, and rear differential has increased in recent years—especially in crew cabs and trucks with longer beds—the prop shaft has been split into two sections. In a split-shaft setup, the center of the prop shaft is held to a frame crossmember by a large stationary center bearing (or carrier bearing), followed by another splined slip joint (rubber booted) and U-joint, for a total of three U-joints.

The most common DIY task performed to a driveshaft is the replacement of one or more of the U-joints, which are under a lot of stress during the transfer of engine power and torque to the wheels, especially in 4WD applications. Over time, the U-joint caps containing needle bearings overheat and distort, creating an obvious squeaking noise or rattle with each prop shaft rotation.

Materials Needed

- Ratchet and socket set

- Torque wrench

- Hydraulic floor jack

- Jack stands (two or three)

Note

Most OEM U-joints don’t have a grease fitting (or Zerk fitting) for repacking the bearings with grease, but many aftermarket U-joints do.

Step 1 – Select the driveshaft type

Replacing an entire driveshaft involves many decisions regarding what materials are used, and requires precise measurements. And because the entire shaft needs to be balanced to attain smooth highway speeds, it’s best to replace a two-piece driveshaft as an entire unit or have the shaft re-manufactured to have a new section added so the entire shaft can be re-balanced.

In addition, many Ram truck owners choose to replace their two-piece prop shaft with a large diameter, one-piece aluminum shaft to help minimize launch shudder. In this case, the center four-bolt carrier bearing support housing also needs to be entirely removed to prevent the driveshaft from rubbing up against it.

A very common driveshaft project has been replacing a two-piece OEM steel driveshaft with a new one-piece shaft, which is typically made from aluminum and with a larger diameter than the original. This is because one-piece aluminum shaft can help minimize launch shudder. Many believe the central carrier bearing is a weak point of the two-piece design. In fact, Dodge has installed a one-piece driveshaft in models that previously came with two-piece units.

Step 2 – Select the driveshaft material

Prop shafts are generally hollow tubes that are available from a diameter of three inches to a massive six inches. They vary in thicknesses and are made from one of the following materials:

- Steel

- Aluminum

- Chromoly

- Carbon Fiber

Most light duty, regular cabs, and two door Ram trucks with a short bed come with a one-piece steel prop shaft. Many of the heavy-duty Ram trucks come with OEM aluminum prop shafts to save weight. The differences in material primarily come down to differences in weight; for example, lighter is better and more versatile, while heavier and stronger have the ability to handle higher RPMs. Additionally, each step up from a steel shaft also increases the price.

Chromoly is a steel alloy that contains chromium and molybdenum (among other elements), which, weight-for-weight, makes it stronger than normal steel. And while it does contain chromium (around 1%), it’s not enough to provide the corrosion resistance found in stainless steel. Its high tensile strength does make it a good choice to use for the re-manufactured prop shafts.

Carbon fiber is a composite material made from thin, strong crystalline carbon filaments embedded in a resin. It’s extremely strong and very light; it's also expensive.

The following chart shows the RPM at which the driveshaft is computer projected (by computer simulation) to bend or whip. Exceeding critical speed would theoretically produce vibrations that would not only result in driveshaft failure, but would also cause damage to the differential’s gears and bearings, as well as the transmission’s torque converter and planetary gears.

Critical RPM Speed Chart (data from Precision Shaft Technologies):

- Mild Steel: 54-inch prop shaft @ 3” x 0.083” = 5,900 RPM

- Chromoly: 54-inch prop shaft @ 3-1/2” x 0.083” = 6,800 RPM

- Aluminum: 54-inch prop shaft @ 3-1/2” x 0.125” = 6,900 RPM

- Carbon Fiber: 54-inch prop shaft @ 3-3/4” x 0.120” = 12,400 RPM

By far, the most common material used for a replacement driveshaft is aluminum. One big driveshaft re-manufacturer claims aluminum is chosen over steel or chromoly by a four-to-one margin.

Prop shaft repairs can be handled by shipping your failed driveshaft to a re-manufacturing facility and having them rebuild it. Custom prop shafts are typically made to order; you're not removing and shipping out your driveshaft, but before you order a new prop shaft for your truck, you’ve got some homework to do.

Step 3 – Identify the transmission/transfer case and remove the driveshaft

The size (length as well as diameter) and number of splines of the slip yoke between the transmission, or transfer case, to the first U-joint must be determined.

For vehicles without the original paperwork, some research to find this information may be in order because the Vehicle Certification Label located on the driver’s side door of all Ram trucks doesn’t display it. For example:

Automatic Transmissions:

- 904: 26 spline, 1-9/16” seal diameter

- 727: 30 spline, 1-11/16” seal diameter

Manual Transmissions:

- A833: 26 spline, 1-9/16” seal diameter

- A833: 30 spline, 1-11/16” seal diameter

The 4WD, 2500, and 3500 series Ram trucks will have heavier-duty components such as 32 and 34 splined transmission slip yokes. The safest way to find this out is to remove the old prop shaft and carefully measure its length, diameter, and spline count.

Driveshaft removal (and installation) is straightforward:

- Using two or three jack stands, support the front and rear ends of the driveshaft. For a two-piece driveshaft, support the center as well.

- Unbolt the rear U-joint or four-bolt flange on the truck's differential pinion.

- Remove the center bearing (carrier bearing) support bracket.

- Pull the slip yoke out from the transmission's (or transfer case's) attachment point.

Pro Tip

Sometimes you’ll see the 727 slip yoke listed as having 29 splines or "29/30." This is because (as shown in Figure 3 above) they are typically manufactured with one spline missing. Functionally, however, they were made to accommodate a shaft with 30 splines, so "30" is correct.

Step 4 – Identify the rear U-joint

If the pinion yoke has placement tabs that hold the U-joint in place, measure the inner dimension between the tabs. If the pinion yoke doesn’t have placement tabs, measure the inside dimension of the yoke opening.

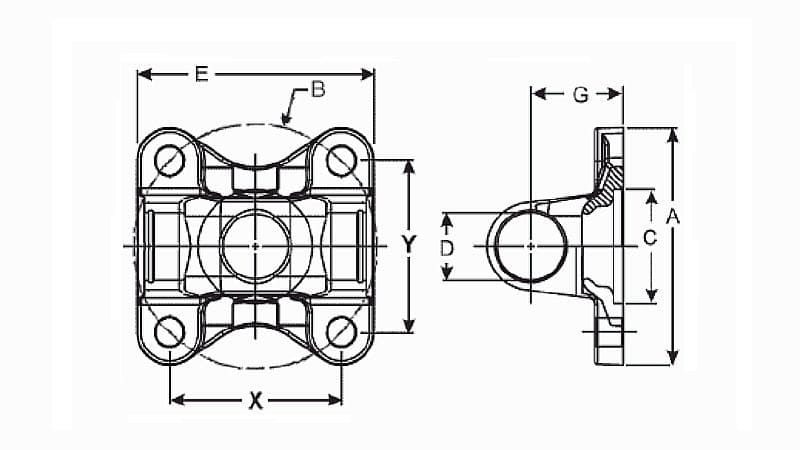

To measure the differential pinion flange, refer to Figure 5 below. The measurements required would be the pilot diameter (C) and bolt hole to bolt hole (B) measured diagonally across from center to center.

Determining the actual U-joint size, called its “series,” can be difficult because there are hundreds of different sizes. However, these five sizes cover most vehicles, with the 1350 typically used on light-duty (1/2-ton) trucks and the 1410 as well as 1480 on heavy-duty (3/4- and 1-ton) trucks:

- 1310 Spicer Series: 1-1/16″ cup Diameter, 3-7/32″ length

- 1330 Spicer Series: 1-1/16” cup diameter, 3-5/8” length

- 1350 Spicer Series: 1-3/16” cup diameter, 3-5/8” length

- 1410 Spicer Series: 1-3/16” cup diameter, 4-3/8” length

- 1480 Spicer Series: 1-3/8” cup diameter, 4-3/16” length.

Step 5 – Measure the driveshaft length

Carefully measure the length of the prop shaft (refer to Figure 6 below). Dimension (A) measures the distance from the mounting face of the transmission (or transfer case) to the pinion yoke mount surface containing four bolt holes.

If you are having a two-piece prop shaft made, measure the distances to and from the center bearing (B and C).

Step 6 – Order and install the new (or re-manufactured) driveshaft

Many companies sell re-built driveshafts and/or driveshaft components, while fewer companies sell new, purpose-manufactured prop shafts. Here are some brands to consider:

- Driveshaft Specialist

- Shaftmasters

- CARDONE

- Precision Shaft Technologies

- Denny's Driveshafts

For more details of each brand, continue reading below (Driveshaft Supplier Review).

To install the new driveshaft, simply follow the removal process in Step 3 in reverse order.

- Support the front and rear end of the driveshaft. For a two-piece driveshaft, also support the center.

- Attach the slip yoke to the transmission (or transfer case).

- Install the center bearing (carrier bearing) support bracket.

- Then bolt in the rear U-joint or four-bolt flange on the truck's differential pinion.

Featured Video: Driveshaft Removal and Universal Joint Replacement

Driveshaft Supplier Review

Driveshaft Specialist

This company offers one-piece aluminum driveshafts for Dodge Ram 2500/3500 trucks, which are five inches in diameter and 0.125 inches thick. For 2003 to 2013 Ram 2500/3500 trucks, all the company needs to know is the exact driveshaft length and nothing else. For the 1410 series (34 spline transmission yoke and rear flange) the price is $695, and for the 1480 series (34 spline transmission yoke and rear flange) the price is $795; shipping costs being between $65 and $80, depending on distance.

Shaftmasters

Shaftmasters manufactures custom steel and aluminum driveshafts for 2WD and 4WD Dodge Ram trucks.

CARDONE

CARDONE Industries has been manufacturing and re-manufacturing new auto parts for over 45 years. It can supply new constant velocity (CV) drive axles for a claimed 96% of all vehicles in operation today, and also sells re-manufactured driveshafts and CV axles. For a 2011 Ram 1500, CARDONE offers a heavy-duty right rear CV axle (A1 CARDONE re-manufactured) available through various retail parts suppliers for around $95.

Precision Shaft Technologies (PST)

PST manufactures custom driveshafts out of carbon fiber, steel, chromoly, and aluminum. The company's website has good information about measuring your shaft (“Drive Shaft 101”). All shafts can be purchased by special order only and are priced based on size, complexity, and the materials chosen.

Denny's Driveshafts

Denny's Driveshafts offers a large assortment of parts, materials, and custom driveshaft choices. Replacement rear driveshafts with the transfer case slip yoke included range from $365 to $475 in price.

Related Discussions and Sites

- How to Remove Rear Driveshaft and U-Joints - DodgeForum.com

- Trouble Removing Driveshaft - DodgeForum.com

- Rear Drive shaft Sizing/Compatibility? Junk Yard Pull - DodgeForum.com

- Drive Shaft Specialist - DriveShaftSpecialist.com

- Shaftmasters - ShaftMasters.com

- CARDONE - Cardone.com

- Precision Shaft Technologies - PSTds.com

- Denny's Driveshafts - DennysDriveshaft.com